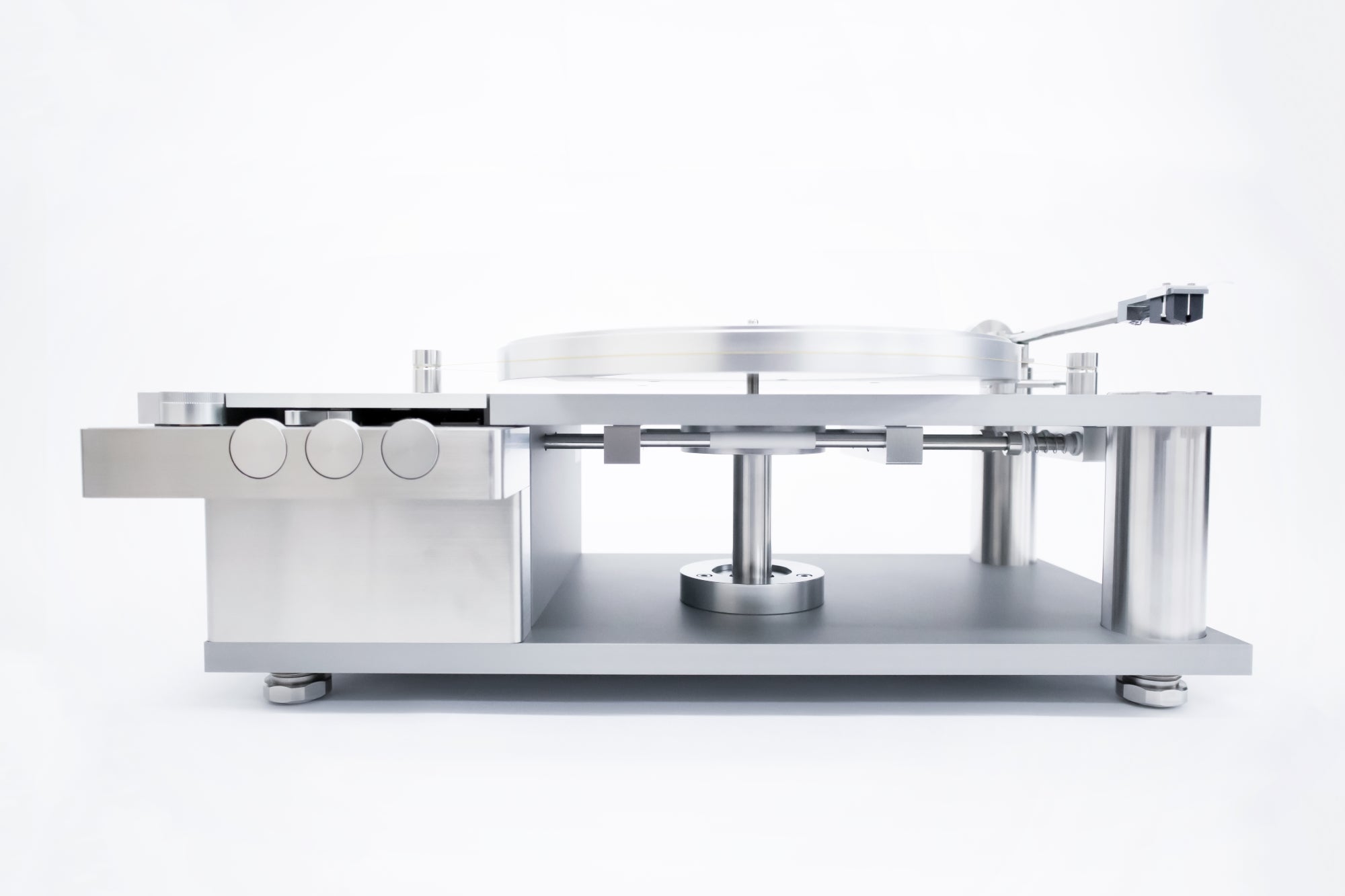

Not just another turntable

Whatever combination you choose, we can help optimize it by setting it all up for you, tracking fine adjustments. Our promise is to offer you a top performing system, delivering maximum performance.

Always.

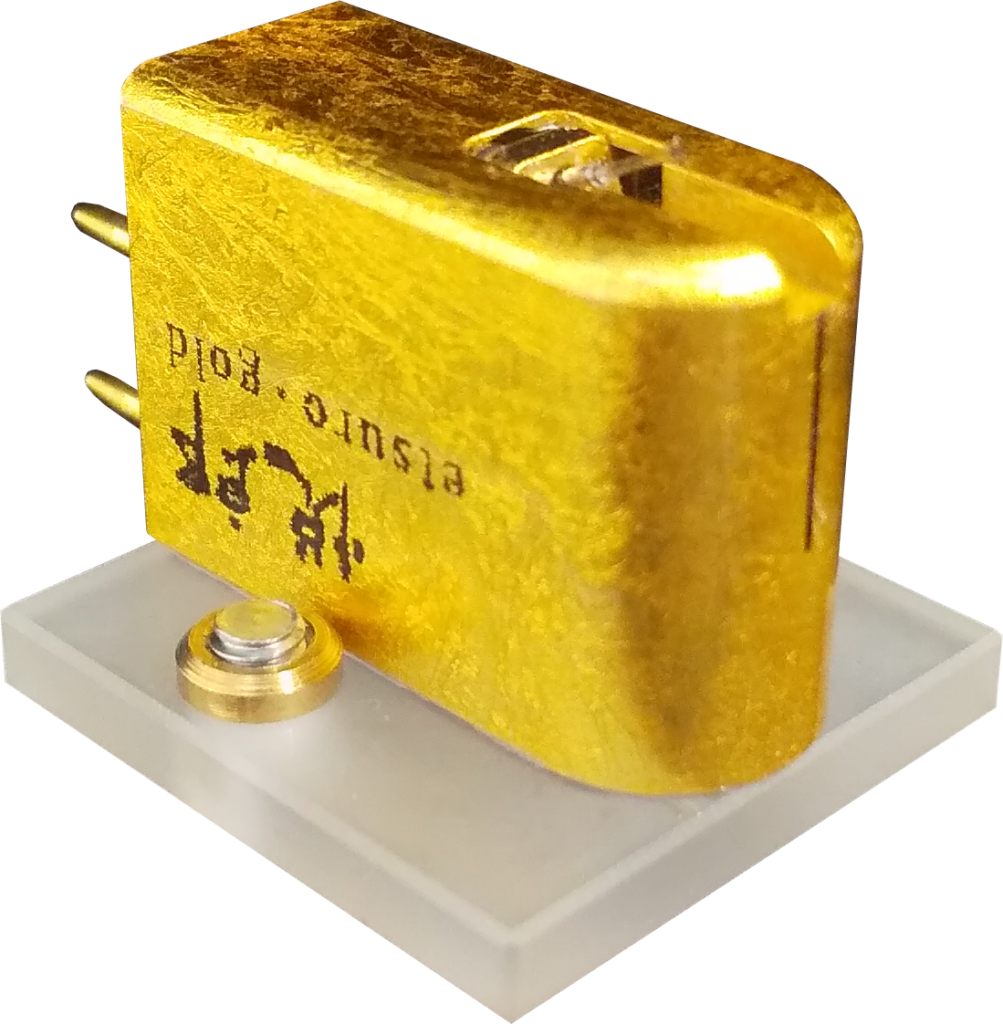

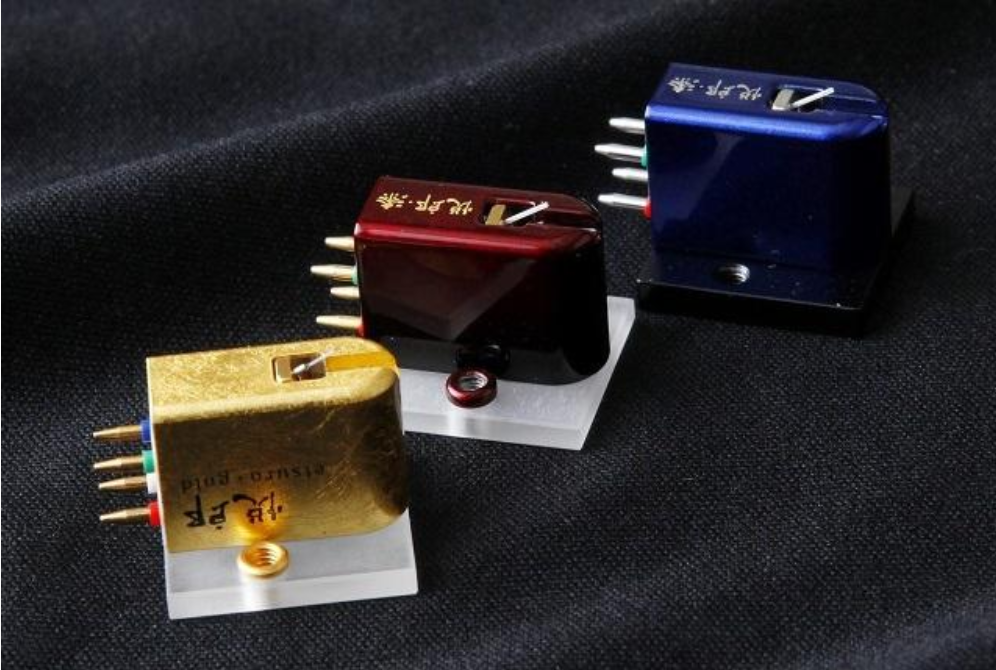

Custom built phono carts

To complement our expertise in cartridges overhaul, we have developed our own range of cartridges based on existing models.

You won't believe your ears when you discover Sculpture A, that's our pleasure promise.

The Full Monty

Browse our full selection of cartridges, tonearms, headshells, cables, plinths, amplifiers and preamplifiers to live the full Ana Mighty Sound experience.

Featuring

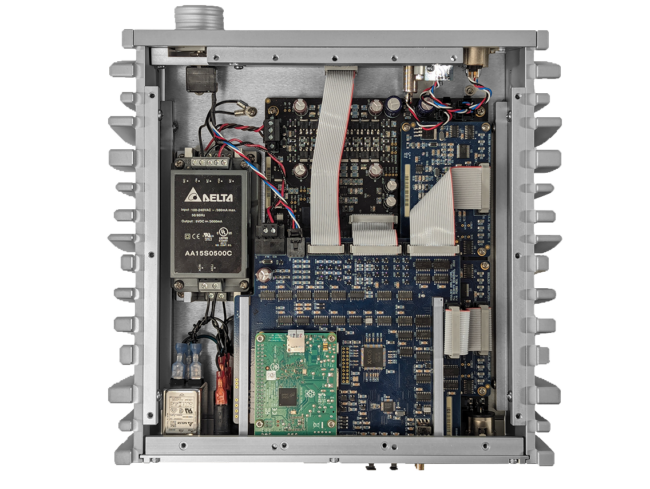

Boulder 508 Phono Preamplifier

Boulder - 812 DAC Preamplifier

Sforzato DSP-09EX - Network Player & DAC

On our blog

A la découverte des enceintes Stenheim